High Purity Zinc Stearate Powder For PVC Film

| Unit Price: | 5 USD |

|---|---|

| Min. Order: | 1 Bag/Bags |

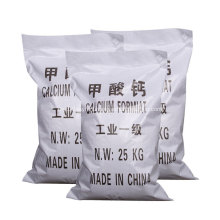

| Packaging: | 20kg/bag, white paper bag or composite kraft paper bag(inside with PE plastics bag). |

|---|---|

| Productivity: | 1000 Ton Per Month |

| Brand: | SKYSIL |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | China |

| Supply Ability: | 10000 Ton Per Month |

| Certificate: | ROHS/ASTM/SGS |

| HS Code: | 2915709000 |

| Port: | Guangzhou,Shenzhen,Shanghai |

Basic Info

Model No.: SKY-1826

Click on the follow link to find out more information: https://www.skychema.com/zinc-stearate-powder/

Company Info

- Company Name: Guangzhou Quanxu Technology Co Ltd

- Representative: Mr Pan

- Product/Service: Paint Matting Agent , Silica Matting Agent , Inkjet Receptive Coating , Nano Alumina , Teflon Heater , Anticorrosion Pigments

- Capital (Million US $): 50000000

- Year Established: 1999

- Total Annual Sales Volume (Million US $): US$50 Million - US$100 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): US$5 Million - US$10 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: High-Tech Development Zone, Guangdong Province, P.R.China

- Contact Person: Mr. Don

- Tel: 86-020-31062685

Premium Related Products

Other Products

Hot Products

Organic Fertilizer Humic Acid Fulvic AcidHigh Quality 40-65g Body Heating PadsChemical Fertilizers Ammonium Sulphate for AgricultureWf Series - Universal Stainless Steel Milling MachineNPK Fertilizer for Hydropnic ApplicationSmall Hand Corn Seeder, Grain Manual PlanterEDDHA Fe 6% Orthor-Ortho 30%-80%Organic Fertilizer Amino Acids PowderAgriculture Battery Powerd Electric Ulv Sprayer (QFG-WS 5CD)Tea Plucking Machine8-20HP Walking Tractor Power TillerBio Organic Seaweed Extract FertilizerLiquid Humic Acid Organic Fertilizer-FancyfertFulvic Acid Organic FertilizerElectric Small Corn Sheller (QFGTL-1)85-100% Soluble Potassium Humate